Jiakaicheng Wealth Center, Financial Third Street, Jiangsu Province, China

Home > Products >

Heating furnace skid rider

Working Temperature:1550 ℃

Compressive strength :4 Mpa under 1200 ℃ Suitable for High temperature , compressive and static environment

Heat-Resist supporting block Cobalt Alloy

- Order phone:+86-13814203326

- E-mail:chao@ytbst.com

Detail

The significance of Skid Rider upgrade

1. Skid riders in heating furnaces are exposed to temperatures above 1250°C for extended periods, with localized areas reaching even higher temperatures. Co50 or Co40 cobalt-based alloys, which have an austenitic microstructure and a melting point ranging from 1380°C to 1420°C, exhibit good plasticity at high temperatures. This plasticity can lead to deformation under heat. Once plastic deformation occurs, localized stress on the skid riders may exceed their high-temperature usage limits, resulting in surface dents or crushing of edges and corners.

2. During the transfer of steel billets in a walking-beam furnace, impacts and side bending of the billets can cause uneven stress distribution on the skid riders.

3. Long-term exposure to high-temperature environments results in thermal corrosion, thermal erosion, and thermal fatigue. Skid riders experience heating from the top due to high-temperature castings and cooling from the bottom due to water cooling, leading to thermal fatigue over prolonged use.

4. The temperature difference between the top and bottom of the skid riders can cause the top temperature to be lower than that of the steel billet, resulting in black marks on the billet surface during production, which affects product quality.

5. Oxidation of steel billets during production leads to the shedding of oxide scales, which can adhere to the skid riders and form nodules, impacting product quality.

Introduction to HHSW Skid Riders Product

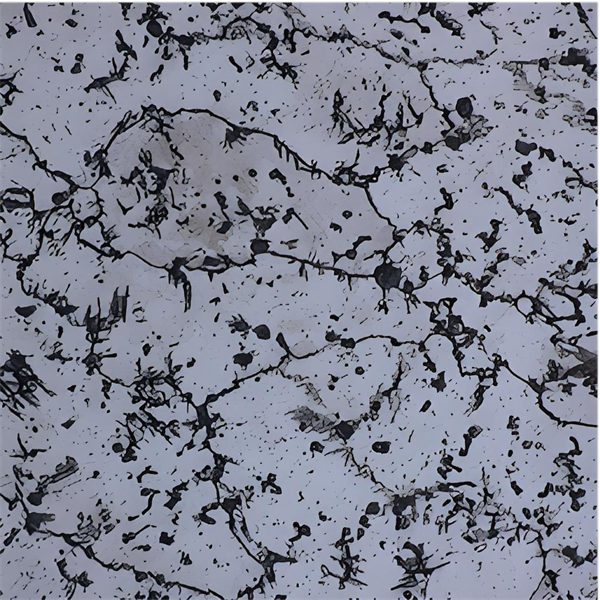

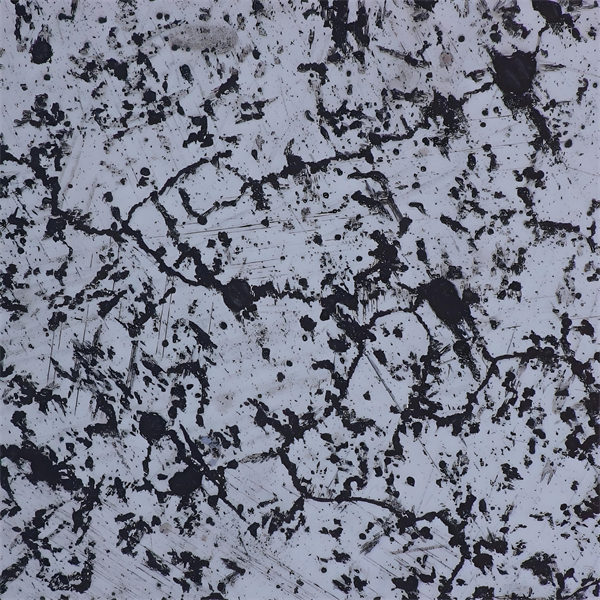

Test and research show that metal glass has a melting point of up to 1,750°C and maintains exceptional compressive strength and oxidation resistance at 1,500°C. Table 1 contrasts the properties of cobalt - based and metal - glass spacer blocks, as detected by oxide layer crystalline phase analysis and high - temperature furnace testing. Thanks to its high - temperature strength and hardness, amorphous structure, and non - bonding with oxide scale, metal - glass spacer blocks are easy to clean and effectively prevent surface defects like lumps and blisters on steel billets caused by oxidized iron scales.

Table 1: Performance Comparison of Cobalt-based Spacer Blocks, Metal-glass Spacer Blocks, and Heating Furnace Spacer Blocks

Product Grade |

Density/

|

Melting

|

Oxidation

|

Maximum service

|

Maximum

|

Co50 |

8.2 | 1380 | 8.63 | 0.98 | 1350 |

Co40 |

8.2 | 1380 | 7.55 | 0.98 | 1350 |

Metallic Glass |

7.7 | 1750 | 2.21 | 4.41 | 1500 |

Heating furnace

|

7.388 | 1750 | 2.00 | 110.00 | 1550 |

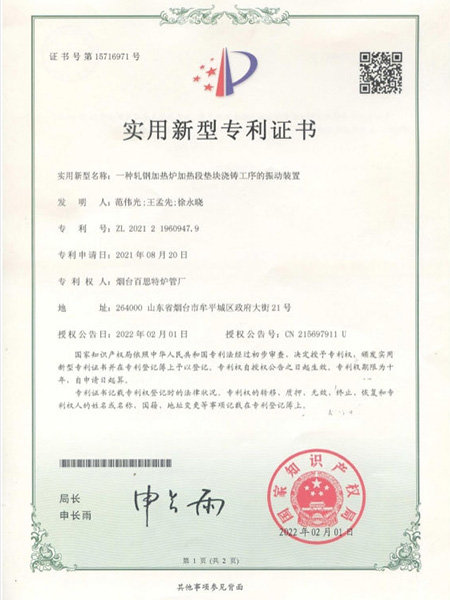

In 2019, Yantai Best Furnace Tube Plant collaborated with Changchun University of Technology, Harbin Institute of Technology (Weihai), and Northeastern University. Building upon metallic glass, they developed a new high-temperature spacer block material named HHSW. This material is distinguished by its ability to withstand higher temperatures, maintain high hardness and strength-toughness, and exhibit superior wear resistance in high-temperature environments.

Tests (see Fig. 3 for the HHSW spacer block test report, dated July 2021) indicate that HHSW spacer blocks have a melting point of 1,750°C, with almost no plastic deformation before melting. Their maximum oxidation resistance temperature reaches 1,550°C. To date, their maximum compressive strength has increased to 110 MPa, with an impact toughness of 39.72 J/cm² , achieving near-zero damage.

Compared to metallic glass spacer blocks, HHSW blocks are less brittle and have higher compressive strength. They have been successfully used in multiple steel plants, including Shougang Qiansteel, Shandong Steel Rizhao, Baosteel Wuhan, and Anfeng Steel. After years of operation, inspections reveal no damage to the spacer blocks' appearance or geometry, with zero wear, as detailed in Table 2.

Table 2: Comparison of Spacer Block Wear

Product Grade |

Original height/mm |

Maximum furnace temperature/℃ |

Measured height/mm |

||

| 1 year | 2 year | 3 years | |||

Co50 |

110 | 1350 | 102 | 95 | 82 |

Co40 |

110 | 1350 | 101 | 93 | 79 |

Heating furnace

|

110 | 1420 | 110 | 110 | 108 |

Sample Name |

Testing Item |

Testing Result |

Unit |

Testing Iethod |

HeatingfurnaceSpacerblock |

Density | 7.388 | g/cm³ | Drainage method |

| Coefficient of thermal expansion | 12.3449*10-6 | 1/K | GB/T 16535-2008 | |

| Melting point | No melting point was detected in the test range from room temperature to 1550℃ |

℃ | GB/T1425-1996 | |

| Oxidation resistance at 1200℃ | 0.01 | g/cm².h | Muffle furnace | |

| 0xidation resistance at 1300℃ | 0.02 | g/cm².h | Muffle furnace | |

| Oxidation resistance at 1350℃ | 0.02 | g/cm².h | Muffle furnace | |

| Indentation depth at 1250℃ under 0.5kg/mm²pressure |

0.04 | mM | High-temperature hardness tester |

|

| Indentation depth at 1300℃ under 0.5kg/mm²pressure |

0.05 | mM | High-temperature hardness tester |

|

| Indentation depth at 1350℃ under 0.5kg/mm²pressure |

0.05 | ITM | High-temperature hardness tester |

|

| Maximum applicable temperature | >1550 | ℃ | Laboratory method | |

| Maximum compressive strength at 1200℃ |

72 | MPa | Universal testing machine |

Figure 3 Inspection Report of Heating Furnace Spacer Block

The development of metal - glass spacer blocks, though solving many problems of traditional cobalt - based alloy ones,still has issues. The main problem is their fragility (solved in heating furnace spacer blocks),and they still use the straddle - clip installation method.

Figure 4 Metallographic Structure of Heating Furnace Spacer Block

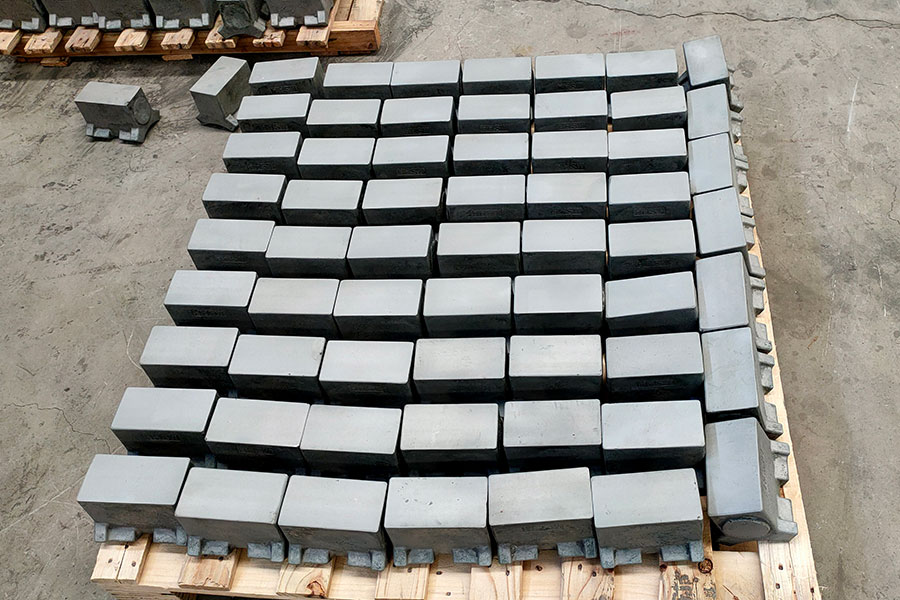

Figure 5 Product Images of Heating Furnace Spacer Block

Comparison Figure

Figure 6 Co50 After One Year of Use (Shansteel Rizhao)

Figure 7 Heating Furnace Spacer Block After One Year of Use (Shansteel Rizhao)

Figure 8 Heating Furnace Spacer Block After Two Years of Use (Shansteel Rizhao)

Figure 9 Installation Image of Heating Furnace Spacer Block (Baotou Steel)

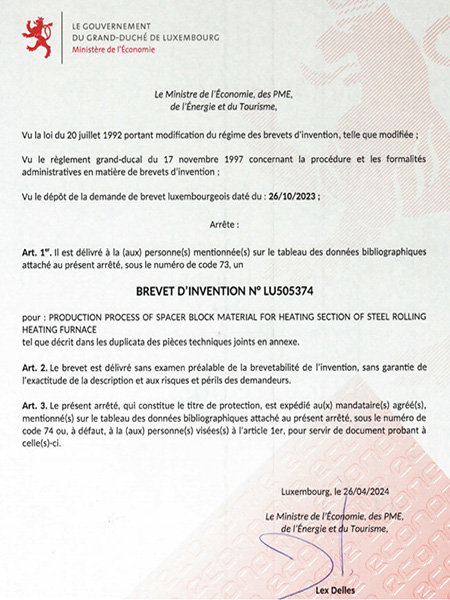

Patent Certificates

Standards Developed

Standardization is essential for national modernization. Our company led the drafting of a national group standard, which has been approved by the China Special Steel Enterprise Association and the Zhongguancun Stainless Steel and Special Alloy New Material Industry Technology Innovation Alliance. The standard, "T/SSEA 0401-2024 Chrome-Alloy Spacer Blocks for Rolling Steel Heating Furnaces," will be released in 2024.

China Special Steel Enterprises Association

Announcement for Group Standards and Codes

No.2024-4(No.048intotal)

The SSEA Group Standard (T/SSEA 0382-2024)for (Steel wire rod forbridge cable wire),(T/SSEA 0383-2024) for (Hot rolled wire rodsfor offshoremooring ropes), (T/SSEA 0384-2024) for (Hot-rolled steel strips for steel pipeswith a longitudinal electric(resistance)weld),(TSSEA 0385-2024)for(Specification for evaluation of China steel products relieved brand Hotrolled H section steel), (T/SSEA 0386-2024)for(Specification for evaluation ofChina steel products relieved brand Hot rolled section steel).(T/SSEA0387-2024)for(Specification for evaluation of China steel productsassured/relieved brand Spring steels),(T/SSEA 0388-2024) for (Specificationfor evaluation of China steel products relieved brand Hot rolled steel bars of carbon structural steel and high strength low alloy strctural steel), (T/SSEA0389-2024)for (Specification for evaluation of China steel products relievedbrand Hot rolled steel strip for general use welding pipe),(T/SSEA0390-2024) for (Quality gradation and evaluation for hot rolled H section steel)(T/SSEA 0391-2024)for (Quality gradation and evaluation for steel plates ofcarbon structural steel and high strength low alloy structural steel). (T/SSEA0392-2024)for (Quality gradation and evaluation for steel plate for buildingstmicture),(T/SSEA 0393-2024)for(Assessment requirements for qualitygrading and forerunner Continuously hot-dip zinc and zinc alloy coated steelsheet and strip), (T/SSEA 0394-2024)for(Assessment requirements for qualitygrading and forennner Heat resistant austenitic stainless steel plate, sheetand strip),(T/SSEA 0395-2024)for(Assessment requirements for qualitygrading and forennner Hot rolled steel strip for battery shell), (T/SSEA0396-2024)for(High resistance alloy wire rod for electrical heating), (T/SSEA0397-2024)for (Continuously cold rolled high strength bake hardening steelsheet and strip for automobile),(T/SSEA 0398-2024)for (Seamless stainlesssteel tubes for precision instruments),(T/SSEA 0399-2024)for (Meltablepolytetrafluoroethylene plastic steel composite tubes for heat exchangers)(T/SSEA 0400-2024)for (Nitrogen alloyed austenitic stainless steel seamlesspipes for seawater pipeline), (T/SSEA 0401-2024)for (Chromium-base alloypad for steel rolling heating furnace), (T/SSEA 0402-2024)for (Spigot gasketjoint spiral steel pipes with corigated reinforcement), (T/SSEA 0403-2024)for (High strength steel plates for tonnage cranes), (T/SSEA 0404-2024)for(High precision steel plate for cmise),(T/SSEA 0405-2024)for (Hot rolledsteel strips for cold rolled oriented electrical steel substrates),(T/SSEA0406-2024)for (Hot rolled steel strips for cold rolled non oriented electricalsteel substrates), (T/SSEA 0407-2024) for (Hot rolled steel plates and strips forhigh-strength automotive wheel rims),(T/SSEA 0408-2024)for (Hot rolled ribbed steel bars for salt alkali resistant reinforced concrete),(T/SSEA0409-2024)for (Continuously cold rolled steel strip for precision refrigeratingwelded tubes),(T/SSEA 0410-2024)for(Technical specification forgreen-design productassessmentHot rolled section steel),(T/SSEA0411-2024)for(Technical requirements for ultra-low emission operationenergy consumption of dust removal facilities in iron and steel enterprises)(T/SSEA 0412-2024)for(Technical requirements for ultra-low emissionoperation energy consumption of sintering fue gas desulfurization anddenitrification facilities in iron and steel enterprises), (T/SSEA 0413-2024) for(Technical requirements for producing rare earth steel by recycling rare earthelements from blast furnace slag) and (T/SSEA 0414-2024) for (Shredded andbundled recycling iron-steel materials) 33 standards were approved by ChinaSpecial Steel Enterprises Association, and now they are effective. Please checkout the attachment for more details.

Performance Table

| Serial Number | Standard Number | Standard Name | Implementation Date |

| 1 | T/SSEA 0382 | Coil for bridge cable wire | 2024-07-01 |

| 2 | T/SSEA 0383 | Hot-rolled coil for marine mooring chain wire rope | 2024-07-01 |

| 3 | T/SSEA 0384 | Hot-rolled steel strip for straight seam electric welded pipe | 2024-07-01 |

| 4 | T/SSEA 0385 | Evaluation criteria for trusted Chinese steel products -Hot- rolled H-beam | 2024-07-01 |

| 5 | T/SSEA 0386 | Evaluation criteria for trusted Chinese steel products -Hot- rolled structural steel | 2024-07-01 |

| 6 | T/SSEA 0387 | Evaluation criteria for trusted Chinese steel products -Spring steel | 2024-07-01 |

| 7 | T/SSEA 0388 | Evaluation criteria for trusted Chinese steel products -Hot-rolled round steel of carbon structural steel and low-alloy structural steel |

2024-07-01 |

| 8 | T/SSEA 0389 | Evaluation criteria for trusted Chinese steel products -Hot- rolled steel strip for general-purpose welded pipe | 2024-07-01 |

| 9 | T/SSEA 0390 | Quality grading and evaluation method for hot-rolled H-beam products | 2024-07-01 |

| 10 | T/SSEA 0391 | Quality grading and evaluation method for steel plate products of carbon structural steel and low-alloy structural steel | 2024-07-01 |

| 11 | T/SSEA 0392 | Quality grading and evaluation method for steel plate products used in building structures | 2024-07-01 |

| 12 | T/SSEA 0393 | Quality grading and "front-runner"evaluation requirements - Continuously hot-dip galvanized steel sheets and strips with zinc alloy coatings |

2024-07-01 |

| 13 | T/SSEA 0394 | Quality grading and "front-runner"evaluation requirements - Heat-resistant austenitic stainless steel sheets and strips | 2024-07-01 |

| 14 | T/SSEA 0395 | Quality grading and "front-runner"evaluation requirements - Hot-rolled steel strips for battery cases | 2024-07-01 |

| 15 | T/SSEA 0396 | High-resistance electric heating alloy coil | 2024-07-01 |

| 16 | T/SSEA 0397 | High-strength cold-rolled bake-hardenable steel sheets and strips for automobiles | 2024-07-01 |

| 17 | T/SSEA 0398 | Stainless steel seamless tubes for precision instruments and meters | 2024-07-01 |

| 18 | T/SSEA 0399 | Heat exchanger pipes of fusible polytetrafluoroethylene steel- plastic composite | 2024-07-01 |

| 19 | T/SSEA 0400 | Nitrogen-containing austenitic stainless steel seamless tubes for seawater piping | 2024-07-01 |

| 20 | T/SSEA 0401 | Chrome-alloy spacer blocks for rolling mill heating furnaces | 2024-07-01 |

| 21 | T/SSEA 0402 | Push-fit joint corrugated reinforced spiral steel pipe | 2024-07-01 |

| 22 | T/SSEA 0403 | High-strength steel plate for cranes | 2024-07-01 |

| 23 | T/SSEA 0404 | High-precision steel plate for cruise ships | 2024-07-01 |

| 24 | T/SSEA 0405 | Hot-rolled steel coils for oriented electrical steel cold-rolled base | 2024-07-01 |

| 25 | T/SSEA 0406 | Hot-rolled steel coils for non-oriented electrical steel cold- rolled base | 2024-07-01 |

| 26 | T/SSEA 0407 | Hot-rolled steel sheets and strips for high-strength automobile wheel rims | 2024-07-01 |

| 27 | T/SSEA 0408 | Reinforcing bars for concrete in saline and alkaline soils,hot- rolled and ribbed | 2024-07-01 |

| 28 | T/SSEA 0409 | Cold-rolled steel strip for precision refrigeration welded tubes | 2024-07-01 |

| 29 | I/SSEA 0410 | Technical specification for green design products -hot-rolled structural steel | 2024-07-01 |

| 30 | T/SSEA 0411 | Technical requirements for energy consumption of dust removal facilities under ultra-low emission in steel enterprises |

2024-07-01 |

| 31 | T/SSEA 0412 | Technical requirements for energy consumption of desulfurization and denitrification facilities under ultra-low emission in steel enterprises |

2024-07-01 |

| 32 | T/SSEA 0413 | Technical requirements for preparing rare earth steel from rare earth elements recycled from blast furnace slag | 2024-07-01 |

| 33 | I/SSEA 0414 | Recycled and baled scrap steel materials | 2024-07-01 |

We also produce cobalt-based pads, which can be customized according to your needs.